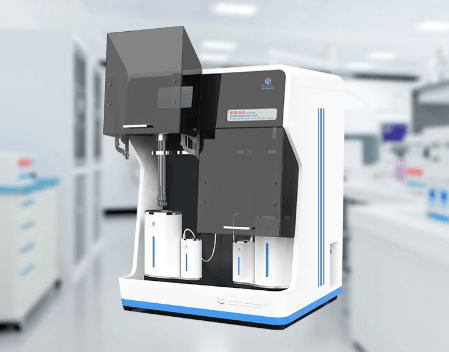

The BSD-660 TG is a cutting-edge, fully automated physisorption analyzer designed for precise surface area and porosity measurements using the volumetric method. Ideal for characterizing materials such as battery cathodes, porous substances, pharmaceutical compounds, and catalysts, the BSD-660 excels in analyzing MOFs, carbon materials, zeolites, LFPs, and various microporous (0.35nm-2nm) and mesoporous (2nm-50nm) materials. Built for high throughput, the BSD-660 enhances lab efficiency by automating tests, reducing manual labor, and improving accuracy. Its innovative A/B station design, with up to 12 in-situ analysis ports, allows independent operation with two gases and different test settings, offering unparalleled flexibility and boosting overall lab productivity.

The PBB Membrane Pore Size Analyzer utilizes the gas-liquid displacement method (bubble pressure method) to accurately measure the pore size characteristics of membrane materials. By applying a pressure difference across the membrane, the system overcomes the surface tension of the infiltration liquid, driving it through the pores to determine pore throat sizes. This method is the standard for ASTM thin film pore size testing. The analyzer is widely used for pore size analysis in materials such as filter membranes, fiber membranes, filter elements, battery separators, fabrics, non-woven fabrics, paper, ceramics, sintered metals, rocks, concrete, and more.

The BSD PHC High-Pressure Adsorption Analyzer is a fully automated, high-efficiency instrument designed for high pressure gas adsorption analysis. With a pressure range of 0-50/69/80 MPa and a temperature range from -196°C to 1100°C, it provides precise and versatile testing capabilities for a wide array of materials. This instrument offers seamless operation and reliable data, making it an ideal solution for advanced adsorption studies in both research and industrial applications.

Based on all functions of PH / PHE / PHU, an optional module is available to apply both axial and radial stresses to intact rock cores and coal cores, simulating in-situ formation stress conditions. This enables the evaluation of CH₄ and CO₂ adsorption performance of rock and coal cores under high-stress conditions, significantly improving the accuracy of gas storage capacity assessment.

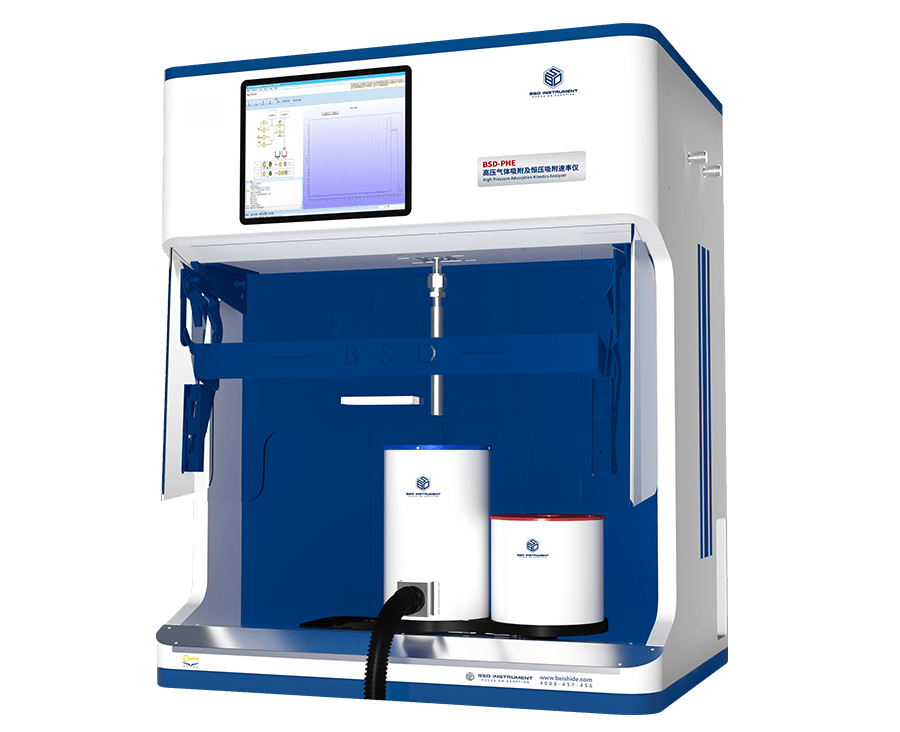

The BSD PHEM High-Pressure Adsorption Kinetics Analyzer is a fully automated, high-efficiency instrument designed for precise gas adsorption analysis under high-pressure conditions. It offers advanced kinetics analysis at isobaric high pressure, making it an ideal and cost-effective alternative to traditional magnetic balance gravimetric analyzers.

Simulates gas outburst and atmospheric-pressure desorption processes of hydrogen and methane storage tanks.

Real-time desorption flow is monitored via multi-stage MFCs to measure the initial desorption rate within 3–10 s, the final desorption rate, and the atmospheric-pressure desorption rate curve.

The system features an optional TPD (Temperature Programmed Desorption) module for programmed temperature desorption, as well as capabilities for hydrogen absorption and desorption kinetics testing. It also supports TPD desorption rate analysis, platform temperature control, and TPA (Temperature Programmed Absorption) hydrogen absorption rate testing, providing comprehensive insights into material behavior under varying temperature and pressure conditions.

With its versatile testing options and high level of automation, the BSD PHE Analyzer delivers reliable, accurate results for a wide range of high-pressure adsorption and desorption applications.

The Gravimetric Sorption Analyzer accurately measures the adsorption and desorption behavior of samples by directly weighing mass changes in real time before and after adsorption, under controlled relative partial pressures. Using a high-precision microbalance, it offers superior accuracy compared to volumetric methods, eliminating common sources of error such as temperature-induced zone distribution and non-ideal gas corrections.

This analyzer overcomes the limitations of volumetric methods by enabling real-time, isobaric adsorption rate measurement and providing precise data on adsorption kinetics, which are essential for understanding material behavior.

The BSD Dynamic Gravimetric Vapor Sorption Analyzer enhances this functionality with high throughput capabilities, allowing for the simultaneous analysis of up to 8 samples. Its fully automated cyclic testing feature significantly boosts laboratory efficiency, reducing the need for repetitive tasks and freeing researchers to focus on more complex analyses.

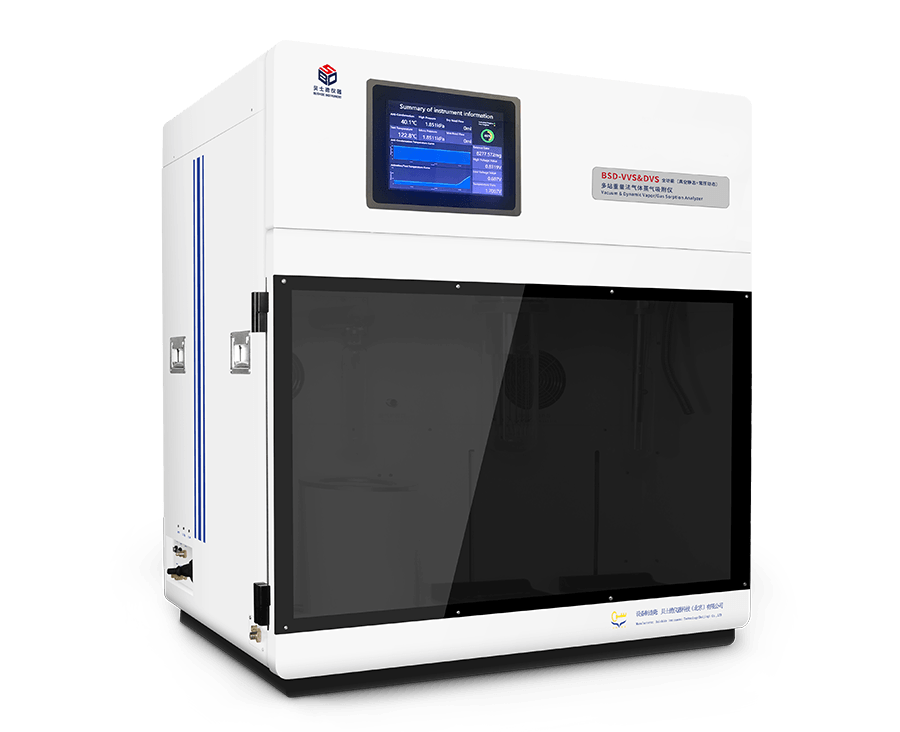

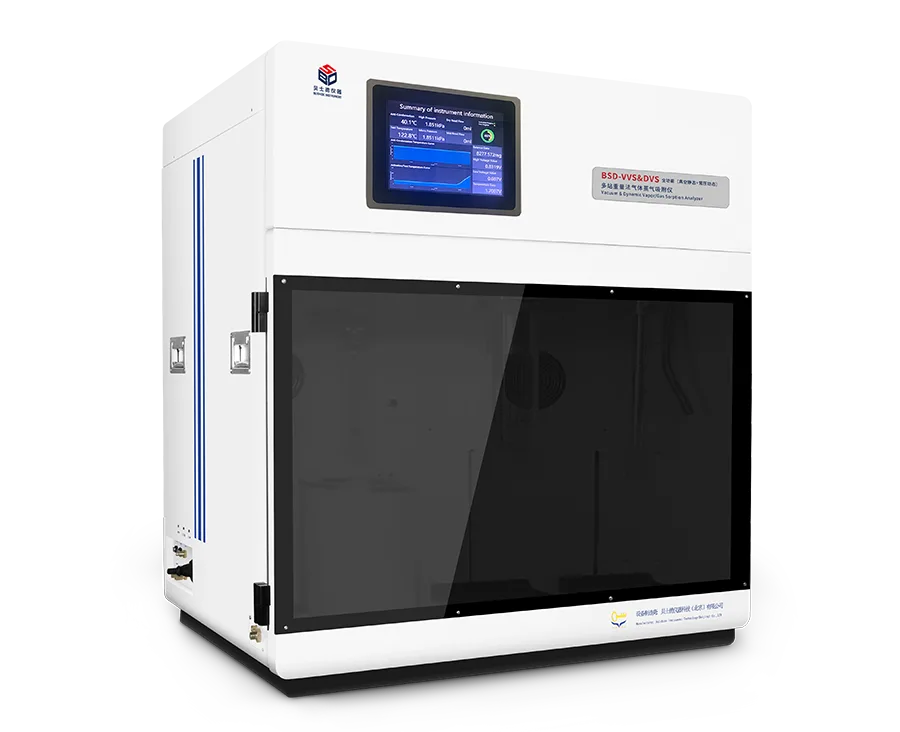

The Gravimetric Sorption Analyzer accurately measures the adsorption and desorption behavior of samples by directly weighing mass changes in real time before and after adsorption, under controlled relative partial pressures. Using a high-precision microbalance, it offers superior accuracy compared to volumetric methods, eliminating common sources of error such as temperature-induced zone distribution and non-ideal gas corrections.

This analyzer overcomes the limitations of volumetric methods by enabling real-time, isobaric adsorption rate measurement and providing precise data on adsorption kinetics, which are essential for understanding material behavior.

The BSD Vacuum Gravimetric Vapor Sorption Analyzer enhances this functionality with high throughput capabilities, allowing for the simultaneous analysis of up to 8 samples. Its fully automated cyclic testing feature significantly boosts laboratory efficiency, reducing the need for repetitive tasks and freeing researchers to focus on more complex analyses.

The versatile, high-performance instrument is designed for comprehensive gas adsorption testing. It supports the adsorption isotherm testing of conventional and flammable gases such as N2, O2, CO, CO2, H2, CH4, and C2H6. The analyzer provides full functionality for analyzing specific surface area, mesopores, micropores, and ultra-micropores. With high throughput capabilities, it offers 3, 6, 9, or 12 analysis positions and features fully automated operation, including degassing and testing cycles. The analyzer automatically cycles through material adsorption performance evaluations, providing reliable, repeatable results.

The versatile, high-performance instrument is designed for comprehensive gas adsorption testing. It supports the adsorption isotherm testing of vapors like H2O and Organic vapor, as well as conventional and flammable gases such as N2, O2, CO, CO2, H2, CH4, and C2H6. The analyzer provides full functionality for analyzing specific surface area, mesopores, micropores, and ultra-micropores. With high throughput capabilities, it offers 3, 6, 9, or 12 analysis positions and features fully automated operation, including degassing and testing cycles. The analyzer automatically cycles through material adsorption performance evaluations, providing reliable, repeatable results.

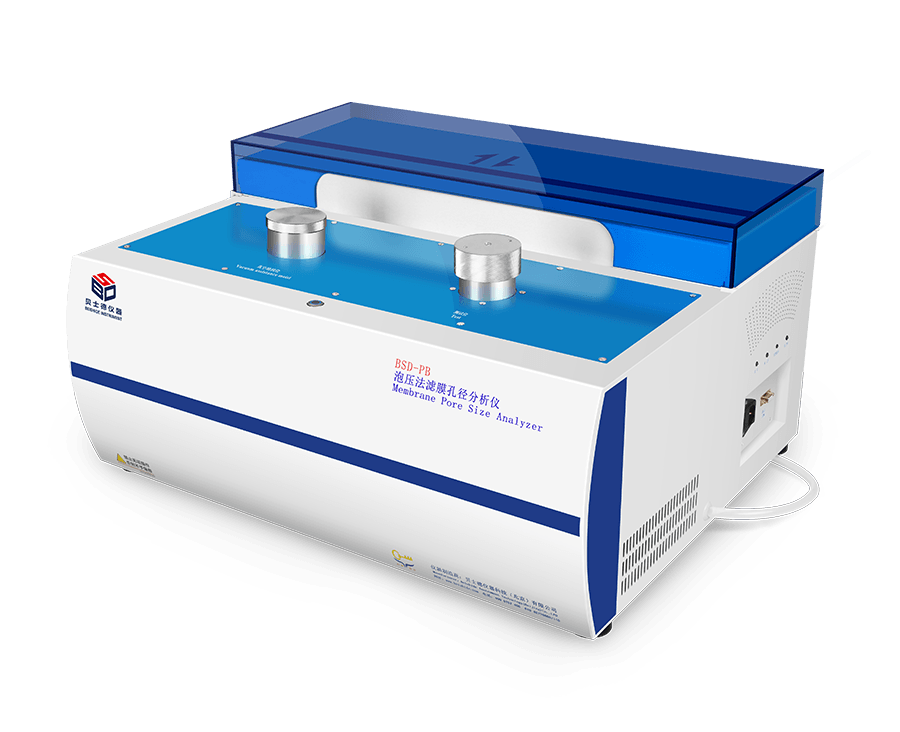

The PB Membrane Pore Size Analyzer utilizes the gas-liquid or liquid liquid displacement method (bubble pressure method) to accurately measure the pore size characteristics of membrane materials. By applying a pressure difference across the membrane, the system overcomes the surface tension of the infiltration liquid, driving it through the pores to determine pore throat sizes. This method is the standard for ASTM thin film pore size testing. The analyzer is widely used for pore size analysis in materials such as filter membranes, fiber membranes, filter elements, battery separators, fabrics, non-woven fabrics, paper, ceramics, sintered metals, rocks, concrete, and more.

The BSD-BET400 is a highly efficient, fully automated instrument designed for testing samples with medium to small specific surface areas using the Dynamic Chromatography Method. It eliminates the need for standard reference materials, ensuring reliable and accurate results. With its exceptional stability, the BSD-BET400 is ideally suited for industrial quality control applications, providing consistent, high-performance testing in demanding environments.