Home / Product / BSD...

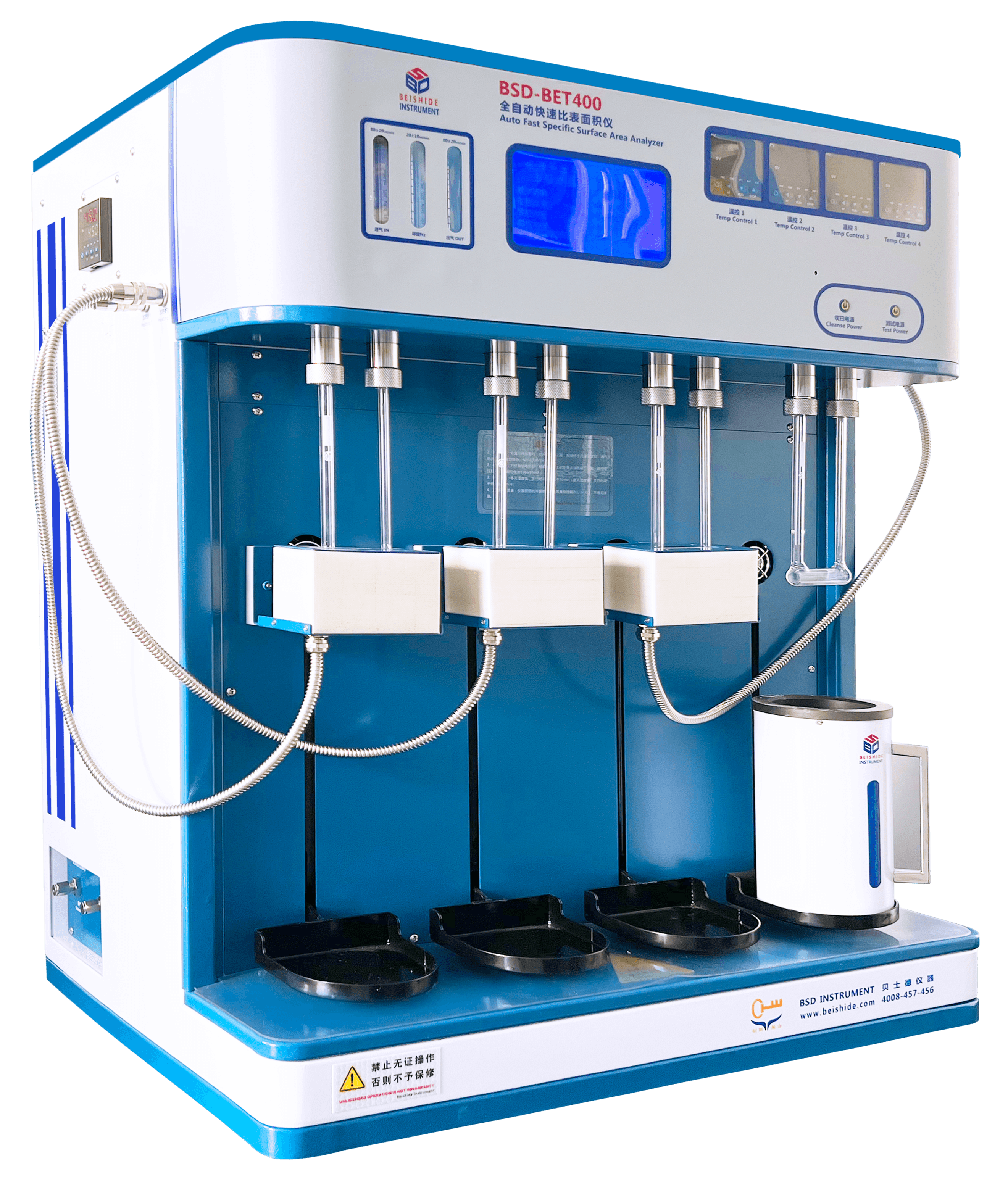

BSD-BET400 AUTO FAST SPECIFIC SURFACE AREA ANALYZER

The BSD-BET400 is a highly efficient, fully automated instrument designed for testing samples with medium to small specific surface areas using the Dynamic Chromatography Method. It eliminates the need for standard reference materials, ensuring reliable and accurate results. With its exceptional stability, the BSD-BET400 is ideally suited for industrial quality control applications, providing consistent, high-performance testing in demanding environments.

- BET single point surface area analysis by dynamic chromatography;

- BET single point surface area analysis by standard sample reference method;

- 4 analysis stations;

- Free of standard sample reference;

- Cold trap to purify gas;

- Analyzer in thermostat;

- High efficiency of testing 4 samples in 20 minutes;