Home / Product / BSD...

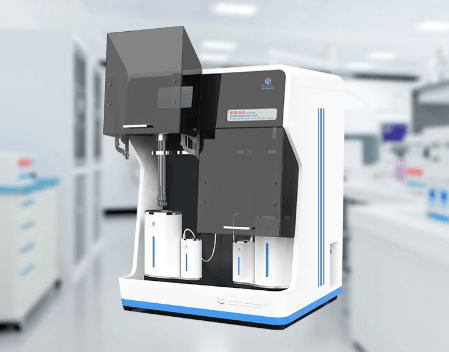

BSD-660 TG Fully Automatic High-throughput Advanced Specific Surface Area and Pore Size Analyzer

The BSD-660 TG is a cutting-edge, fully automated physisorption analyzer designed for precise surface area and porosity measurements using the volumetric method. Ideal for characterizing materials such as battery cathodes, porous substances, pharmaceutical compounds, and catalysts, the BSD-660 excels in analyzing MOFs, carbon materials, zeolites, LFPs, and various microporous (0.35nm-2nm) and mesoporous (2nm-50nm) materials. Built for high throughput, the BSD-660 enhances lab efficiency by automating tests, reducing manual labor, and improving accuracy. Its innovative A/B station design, with up to 12 in-situ analysis ports, allows independent operation with two gases and different test settings, offering unparalleled flexibility and boosting overall lab productivity.

- High-throughput and Fast Specific Surface Area Analysis;

- Pore Volume and Meso-, Micro-, Ultra Micro-pore SizeDistribution Analysis;

- Regular gas, such as N2 , Kr, O2 , Ar, CO2 ;

- Other gas, such as Hydrocarbon C1-C4, CO, NH3 ;

- Test Range: ≥0.01 m2/g (N2) and 0.005 m2 /g (Kr), pore size distribution: 0.35 – 500 nm;

- High Accuracy: < 0.5% RSD of surface area, pore size, pore volume, adsorption capacity and quantitative error(BET value of standard Sample asreference);

- Pressure Transducer: Transducers are equipped for each analytic station, P0 station and calibrated volume respectively, 1000 Torr * 5, 10 Torr* 3, 0.1 Torr * 3, which work independently with precision at 0.15%;

- Vaccum System: Vacuum can reach 10-2 Pa with mechanical pump while can reach 10-8 Pa with molecular pump.

- Heater: temperature control range 25 – 500℃ ;

- Water bath: temperature control range -10 – 80℃ ;

- Dewar vessel capacity: 3L;

- Valve:Pneumatic valve with metal seal;

- Data report:Isotherm, BET, Langmuir, BJH,Dollimore-Heal (DH), DA, t-plot, MP, HK, SF, NLDFT, GCMC;

- Accessories: Liquid Nitrogen tank , Sample Cell, Glass rod, Glass funnel, Sample Cell Rack;