Hydrogen Storage Metal Solution

Introduction

introduction to Adsorption Solution for Hydrogen Storage Metal

Hydrogen storage using metal hydrides is a highly efficient and safe method for storing hydrogen. This solution focuses on optimizing the adsorption process with metal hydrides to maximize storage capacity and efficiency.

Process Optimization:

Adsorption Kinetics

- Optimize contact time between hydrogen and metal hydride to maximize adsorption rates.

- Use dynamic adsorption models to predict and enhance adsorption performance

Temperature and Pressure Control

- Maintain optimal temperature and pressure conditions to maximize adsorption capacity.

- Implement advanced control systems to ensure stable and efficient operation.

Regeneration of Metal Hydrides

- Develop efficient regeneration methods to restore metal hydride capacity.

- Utilize thermal or vacuum regeneration techniques to desorb hydrogen from metal hydrides.

Performance Evaluation

01

Hydrogen Production: Hydrogen Purification and Adsorptive Separation Material Evaluation

- Addressing the core requirements of hydrogen production processes, this system provides comprehensive performance characterization of key materials used in hydrogen purification. The focus is on evaluating the selective adsorption capability of adsorptive separation materials toward impurity gases, ensuring that hydrogen purity meets industrial application standards.

- Competitive adsorption testing of multicomponent gas mixtures (e.g., separation of H₂ from impurities such as CO₂ and N₂)

- Breakthrough curve analysis of adsorptive separation materials for optimization of hydrogen purification process parameters

- Cyclic adsorption performance evaluation of materials to ensure long-term operational stability and durability

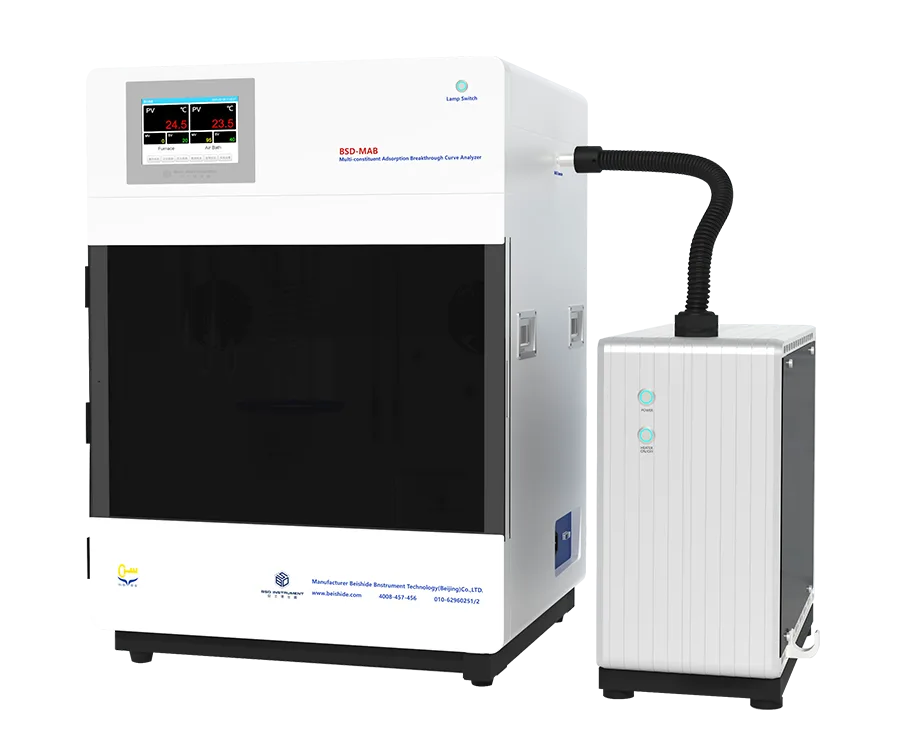

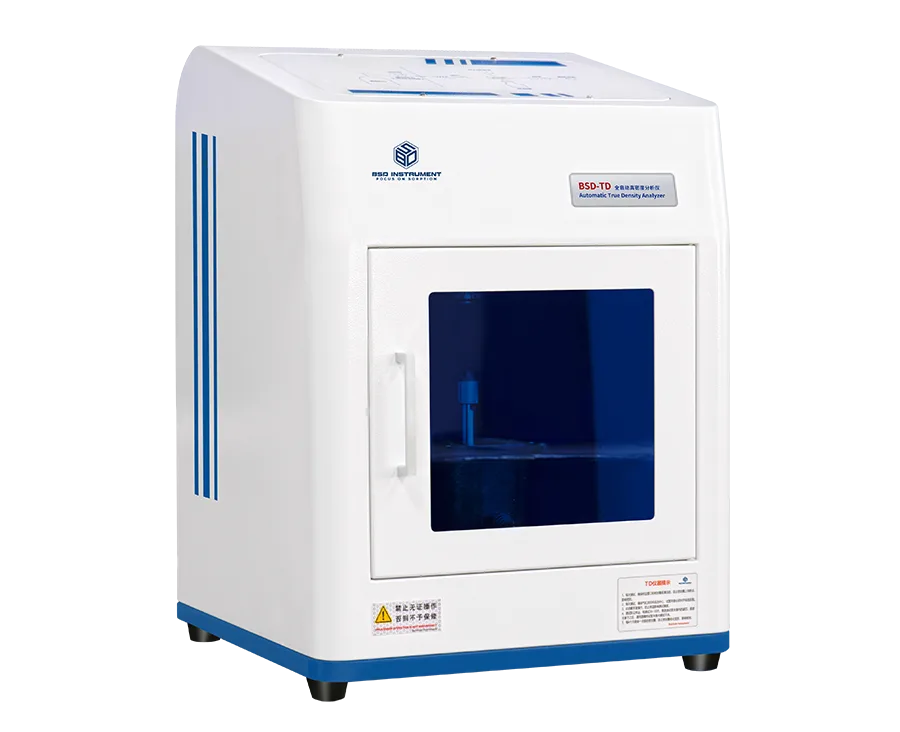

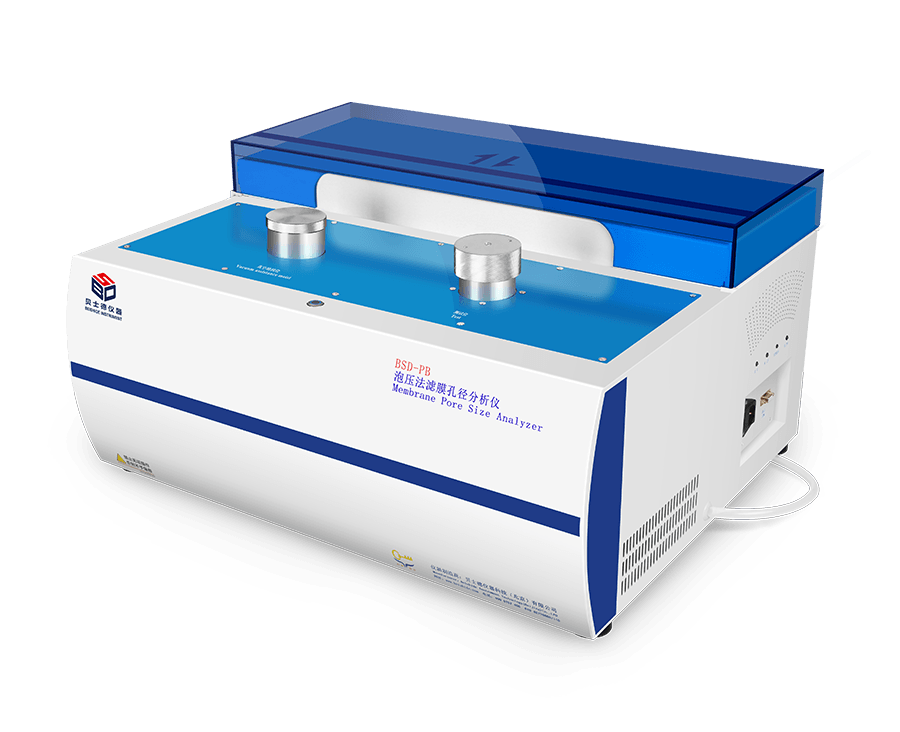

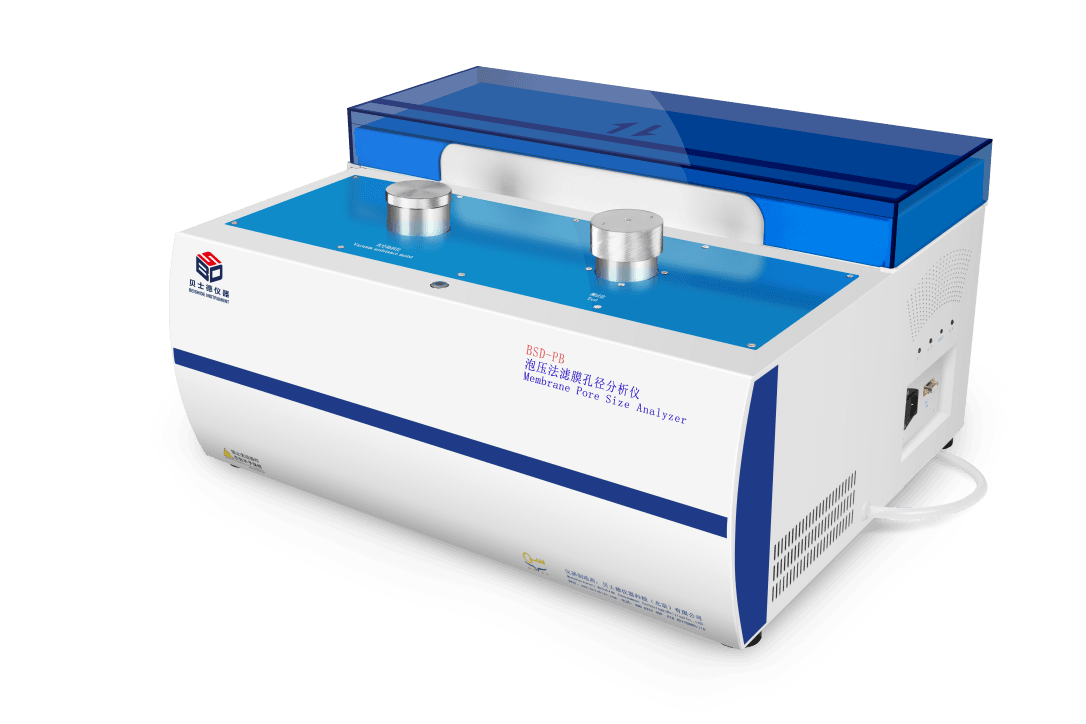

BSD-MAB(Evaluation of adsorbent performance for H2 separation and purification); BSD-TD-K(Porosity); BSD-PB(Pore size distribution)

02

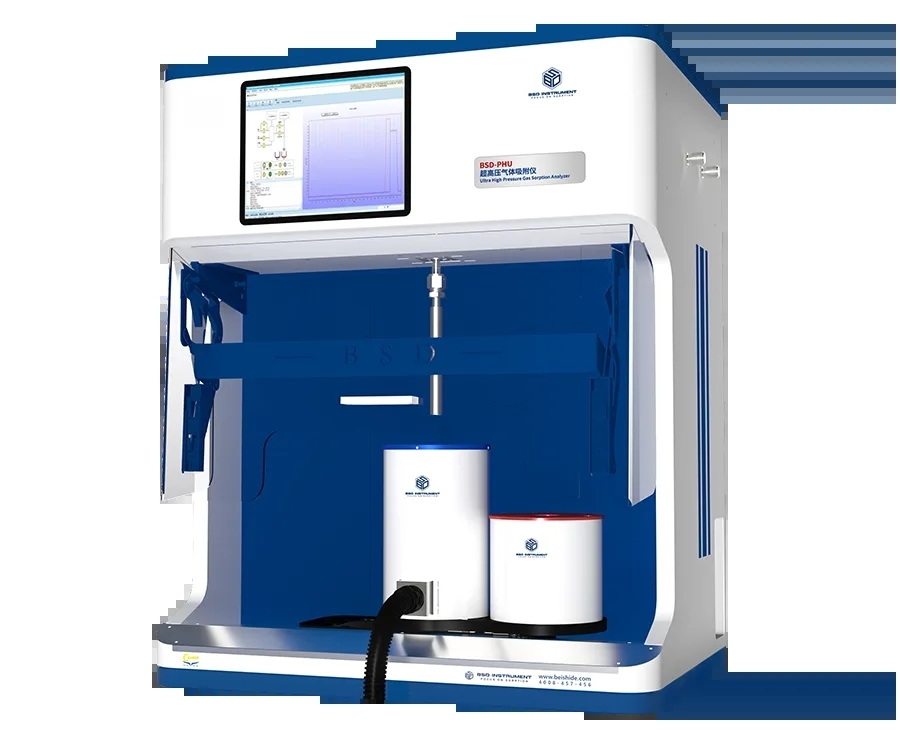

Hydrogen Storage: Characterization of Adsorptive Hydrogen Storage Materials

- Focusing on the core aspects of adsorptive hydrogen storage technology, this system enables comprehensive evaluation of hydrogen storage materials, including hydrogen uptake capacity, adsorption/desorption kinetics, and cyclic stability. The results provide critical data support for material development and hydrogen storage system design.

- High-pressure H₂ adsorption isotherm measurements (0–690 bar) for accurate determination of hydrogen storage capacity

- Dynamic analysis of hydrogen absorption and desorption rates to optimize the response efficiency of hydrogen storage systems

- Hydrogen storage performance testing under wide temperature ranges (–196 °C to 400 °C) to simulate practical operating conditions

- Long-term cyclic hydrogen absorption/desorption lifetime evaluation over thousands of cycles to verify material durability

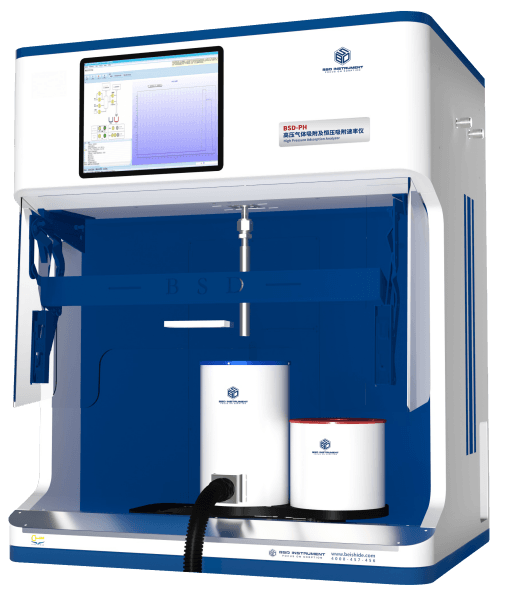

BSD-PH (0-20MPa, PCT Platform) + BSD-LNT(110K-Ambient Temp); BSD-PHU(0-50MPa, 0-69MPa, PCT Platform)

03

Hydrogen Refueling: Constant-Pressure Hydrogenation Technology and Adsorption Performance Testing

- Addressing the requirements of hydrogen refueling stations and hydrogenation equipment, this system provides adsorption capacity and adsorption kinetics measurements under constant-pressure conditions, ensuring both safety and efficiency during the hydrogen refueling process.

- Accurate constant-pressure adsorption capacity measurements (adjustable from 0 to 200 bar) to match various hydrogen refueling pressure requirements

- Constant-pressure adsorption kinetics analysis to obtain adsorption rate curves during the hydrogenation process

- Full gas-line oil-bath temperature control (patented technology) to ensure high data stability and reproducibility

- Evaluation of pressure resistance and adsorption stability of hydrogenation materials

BSD-PHE(Constant-Pressure H₂ Absorption Kinetics)

04

Hydrogen Release: Precise Characterization of Hydrogen Desorption Rate and Capacity

- Focusing on the key performance metrics of the hydrogen release stage, this system enables real-time monitoring and quantitative analysis of hydrogen desorption rate and total released hydrogen, providing a solid basis for optimizing the discharge efficiency of hydrogen storage systems.

- Atmospheric and high-pressure hydrogen desorption rate measurements to obtain hydrogen desorption kinetics curves

- Accurate quantification of released hydrogen capacity to verify the practically usable hydrogen storage capacity of materials

- Comparative evaluation of hydrogen desorption performance at different temperatures to optimize hydrogen release process conditions

- Simultaneous assessment of material structural stability during hydrogen release

BSD-PHEM (kg level sample absorption and desorption analysis, Temperature-Programmed H₂ Desorption Kinetics)

05

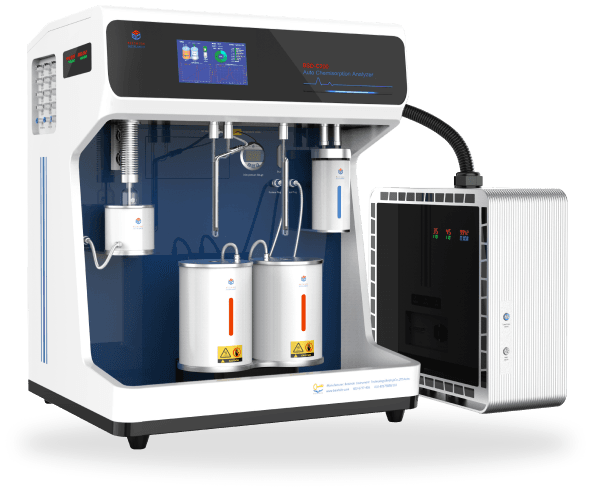

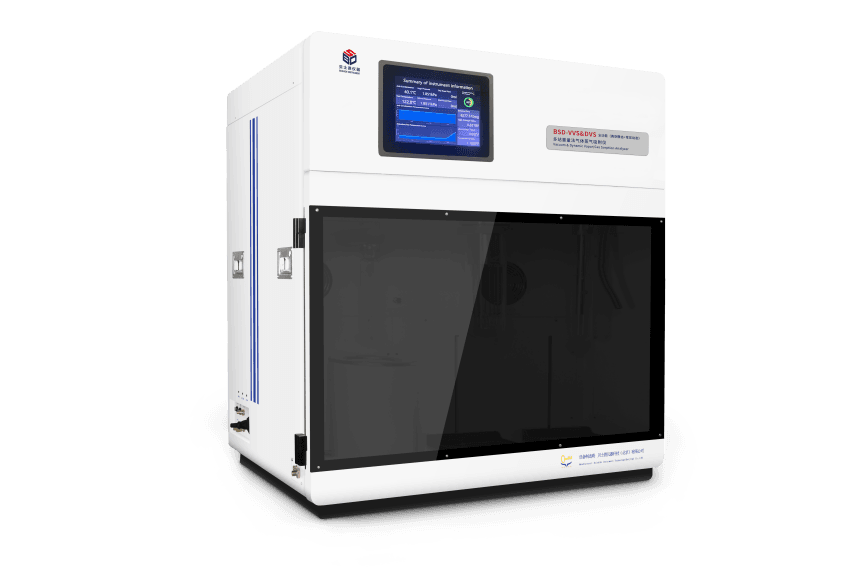

Hydrogen Fuel Cells: Core Material Performance Characterization

- Targeting key components of hydrogen fuel cells, this solution provides dedicated characterization of core materials such as proton exchange membranes, gas diffusion layers, and carbon paper, ensuring both performance and service life of fuel cell systems.

- Proton Exchange Membranes (PEM): Water vapor adsorption capacity and adsorption kinetics measurements to optimize membrane hydration performance

- Gas Diffusion Layers (GDL): Gas diffusion coefficient measurements to evaluate mass transfer efficiency

- Carbon Paper: Pore size distribution, maximum pore size, and gas permeability measurements to optimize electrode structural design

- Catalysts: Chemisorption analysis (TPD / TPR) to evaluate the density and strength of active catalytic sites

BSD-660M(BET SSA of catalysts); BSD-C200(Active surface site characterization of catalysts); BSD-DVS(Moisture uptake performance evaluation of proton exchange membranes); BSD-MASS(Real-time monitoring of H₂, N₂, and O₂ concentrations); BSD-PB(Carbon paper pore size distribution, and gas permeability); BSD-TD-K(Porosity of carbon paper)

Conclusion

Conclusion

Implementing an optimized adsorption solution for hydrogen storage using metal hydrides can significantly enhance storage efficiency and capacity. By selecting appropriate metal hydrides, optimizing storage conditions, and refining process parameters, we can achieve higher hydrogen storage densities with lower energy consumption. This solution supports the advancement of hydrogen as a sustainable and environmentally friendly energy carrier.