Home / Blog / Advanced Characterization of Porous Materials Using a BET Adsorption Analyzer: Principles and Applications

Advanced Characterization of Porous Materials Using a BET Adsorption Analyzer: Principles and Applications

06 1 月, 2026From: BSD Instrument

Abstract

Porous materials play a critical role in catalysis, energy storage, gas separation, and environmental remediation. Accurate characterization of their surface area, pore size distribution, and porosity is essential for understanding their performance and optimizing their design. The Brunauer–Emmett–Teller (BET) theory, applied through gas adsorption analyzers, provides a powerful method for such quantitative analysis. This article reviews the fundamental principles of the BET method, the operation of modern BET adsorption analyzers, and recent advances in data processing and interpretation. Representative applications in nanomaterials, activated carbons, zeolites, and metal–organic frameworks (MOFs) are discussed to illustrate the versatility and importance of this technique in both research and industrial quality control.

1. Introduction

The properties of porous solids are largely determined by their specific surface area, pore volume, and pore size distribution. These parameters influence adsorption capacity, catalytic activity, mechanical strength, and transport phenomena within the material. Among various characterization techniques, gas adsorption analysis based on the BET theory remains one of the most widely used due to its reliability, relatively simple sample preparation, and ability to provide fundamental thermodynamic information.

Modern BET adsorption analyzers allow high-precision measurements over a wide range of pressures and temperatures, enabling detailed investigation of micro-, meso-, and macroporous structures. This paper aims to present an up-to-date overview of the principles, instrumentation, and applications of BET adsorption analyzers in advanced materials characterization.

2. Principles of the BET Theory

The BET model extends the Langmuir theory to multilayer adsorption, assuming that the first layer follows a specific heat of adsorption different from subsequent layers, which behave like liquefaction. The BET equation is expressed as:

where:

- : equilibrium pressure of adsorbate gas

- : saturation vapor pressure at measurement temperature

- : volume of gas adsorbed

- : monolayer adsorption capacity

- : BET constant related to the energy of adsorption

From the linear plot of versus , one can determine and calculate the specific surface area using:

where is Avogadro’s number, is the cross-sectional area of the adsorbate molecule, and is the molar volume of the gas.

3. Instrumentation and Experimental Procedure

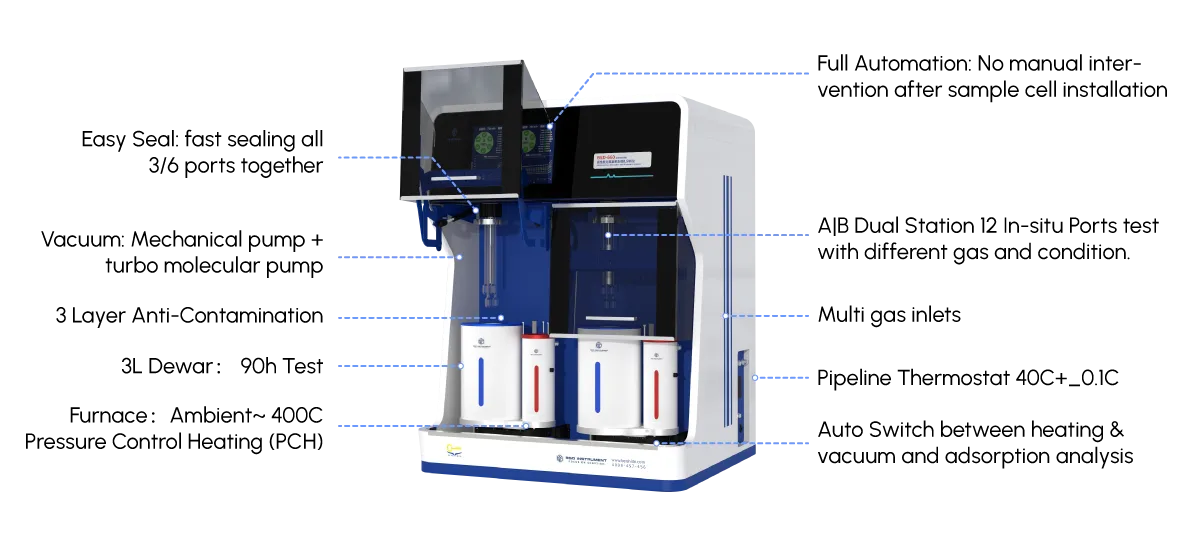

A typical BET adsorption analyzer consists of:

- Sample cell with controlled temperature (commonly liquid nitrogen temperature for N₂ adsorption)

- Gas dosing system for precise pressure control

- Pressure transducers and vacuum pumps

- Data acquisition and analysis software

Procedure:

- Sample pretreatment: degassing under vacuum or inert gas flow to remove physisorbed contaminants.

- Adsorption measurement: incremental doses of adsorptive gas (e.g., N₂, Ar, CO₂) are introduced, and equilibrium pressure is recorded after each dose.

- Desorption measurement (for hysteresis analysis and pore size distribution calculations).

- Data processing: linear BET range identification, calculation of surface area, and pore structure analysis via t-plot, BJH, or DFT models.

4. Advanced Data Analysis

Recent developments include:

- Automated BET range selection using statistical criteria to avoid subjective errors.

- Combined methods: integrating BET surface area with DFT pore size distributions for comprehensive pore structure characterization.

- Multigas adsorption studies to probe site-specific interactions and chemical heterogeneity.

5. Applications

5.1 Nanomaterials

BET analysis is crucial for evaluating carbon nanotubes, graphene-based materials, and nanoparticles where surface area directly correlates with functional performance.

5.2 Activated Carbons

Used in water treatment and supercapacitors; BET combined with pore size distribution reveals optimal adsorption characteristics.

5.3 Zeolites and MOFs

Precise determination of micropore volumes aids in catalyst design and gas separation applications.

5.4 Industrial Quality Control

Standardized BET measurements ensure consistency in production batches of adsorbents and catalysts.

6. Conclusion

The BET adsorption analyzer remains an indispensable tool for the advanced characterization of porous materials. Its ability to deliver accurate surface area and porosity data underpins research and development across multiple disciplines. Continued improvements in automation, data analysis algorithms, and integration with complementary techniques will further enhance its capabilities, supporting the design of next-generation functional materials.

Our Latest Blog & Articles

Stay updated with our latest news. Discover new product launches, innovative technologies, and upcoming events. Join our community and stay informed about all things lab equipment.

-

16 1 月, 2026

Advanced Applications of BET Adsorption Instrument in Nanomaterial Characterization

-

6 1 月, 2026

Advanced Characterization of Porous Materials Using a BET Adsorption Analyzer: Principles and Applications

-

29 12 月, 2025

Static Adsorption Mechanisms: A Comprehensive Review of Theoretical Models

-

23 12 月, 2025

Desorption Isotherm Modeling: A Review of Current Approaches and Challenges