Home / Product / BSD...

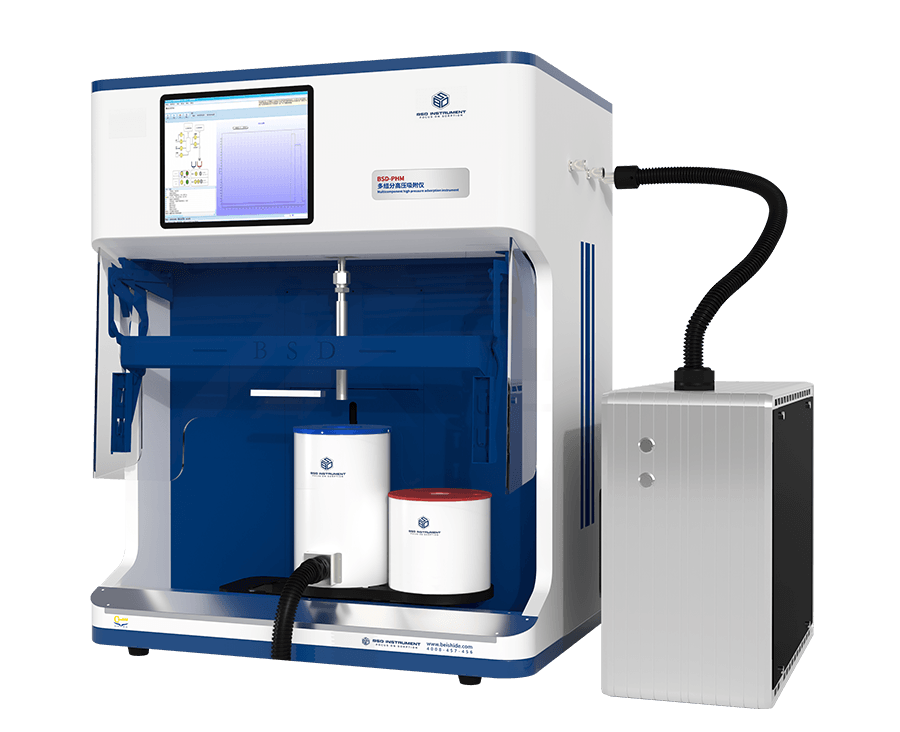

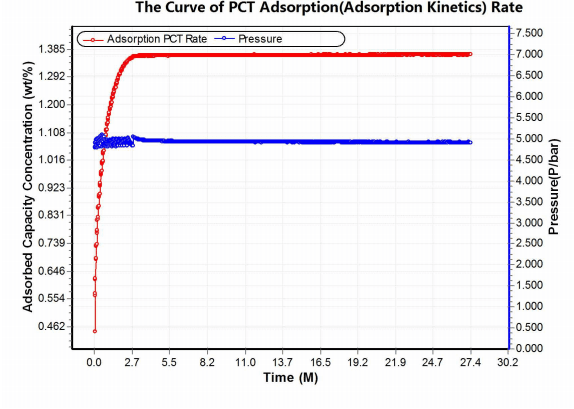

BSD-PHM Multi Components HIGH PRESSURE GAS SORPTION ANALYZER

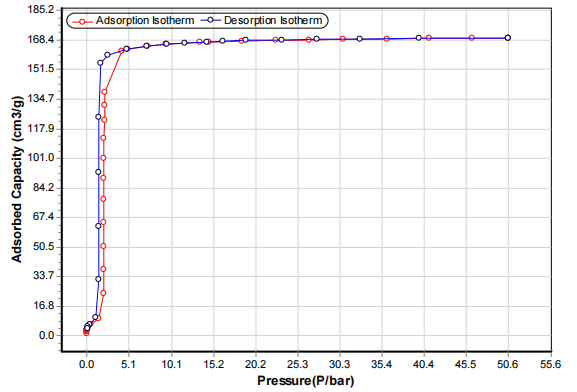

- Pressure upto 20 Mpa;

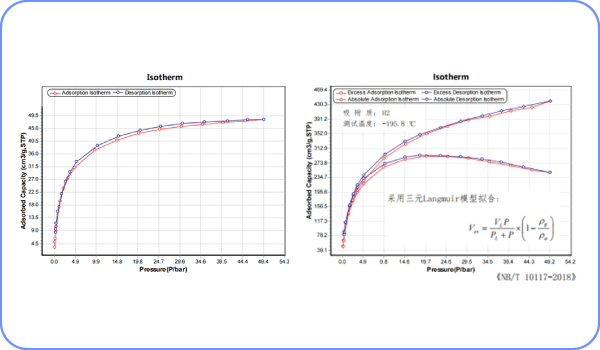

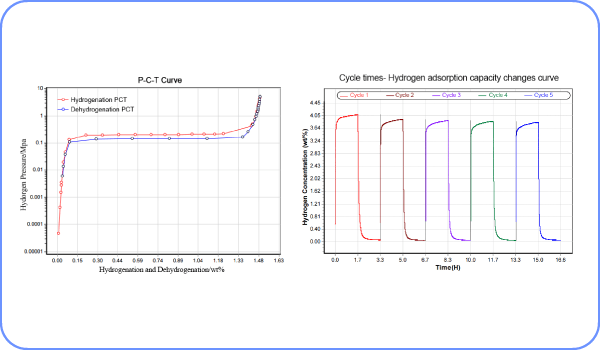

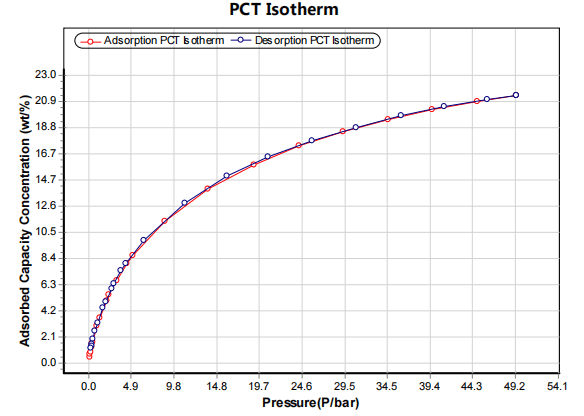

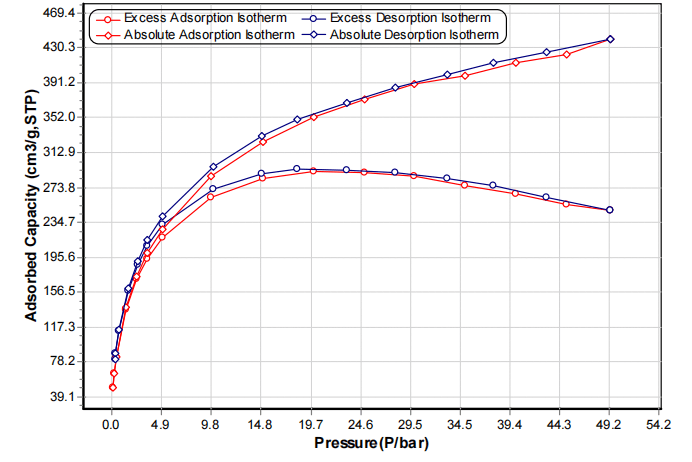

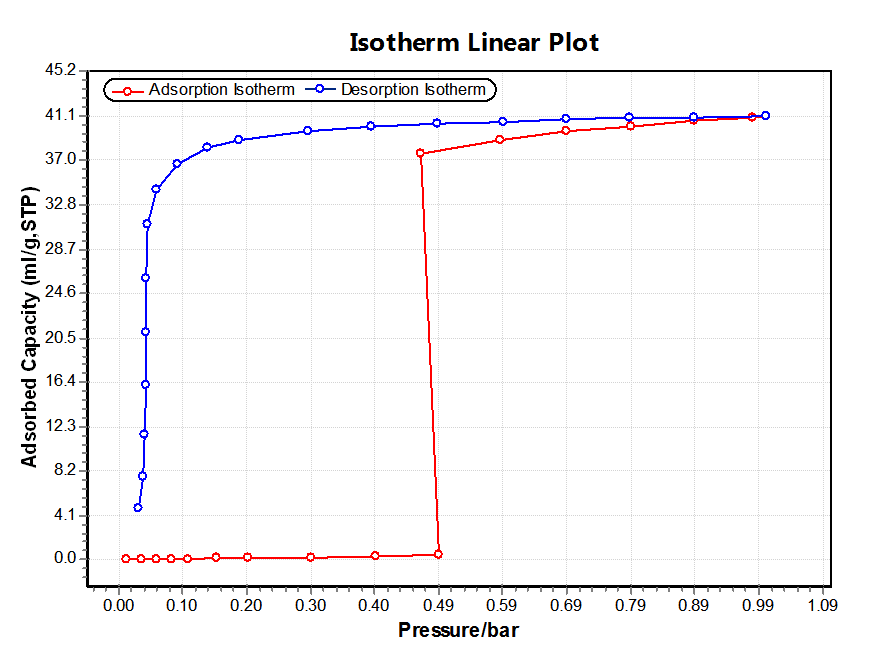

- High pressure multi-component selective/ competitive adsorption analysis;

- Material selectivity analysis;

- High-pressure gas separation analysis;

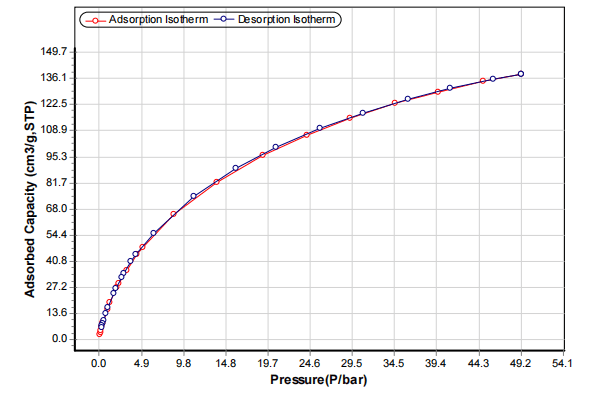

- High pressure mixed gas storage analysis;

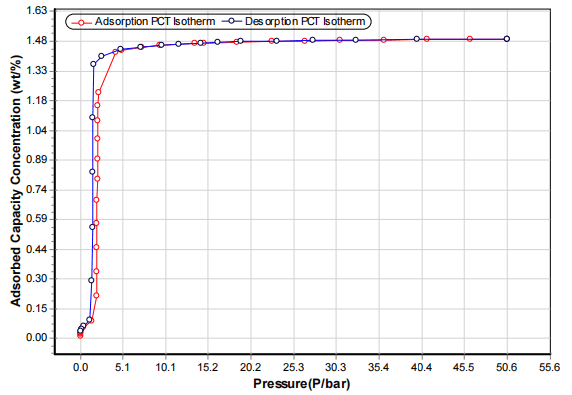

- Shale gas and coalbed methane reserve assessment research;