Home / Product / BSD...

BSD-660MC AUTOMATIC CORROSIVE GAS ADSROPTION ANALYZER

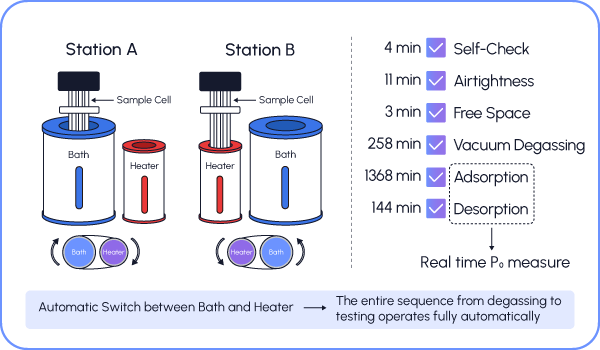

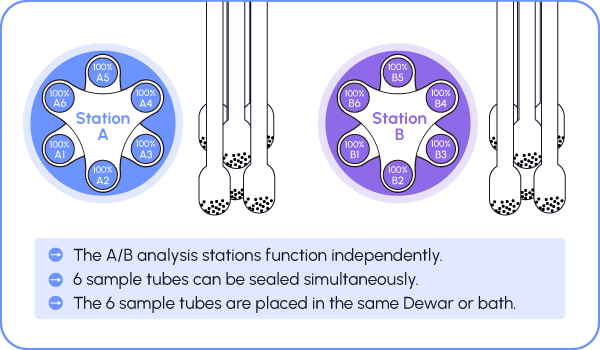

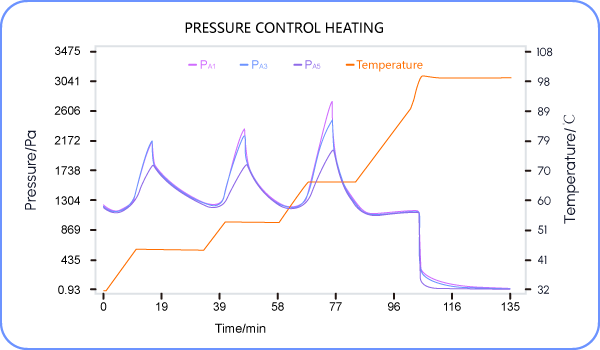

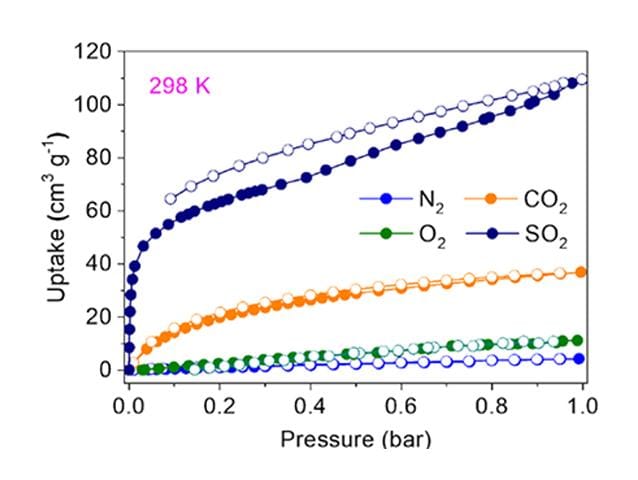

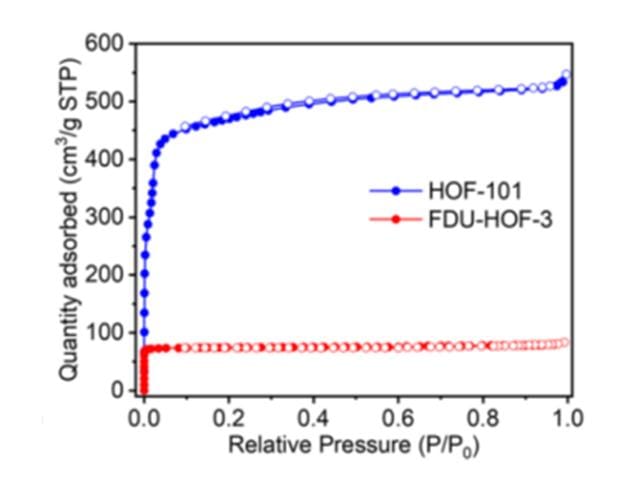

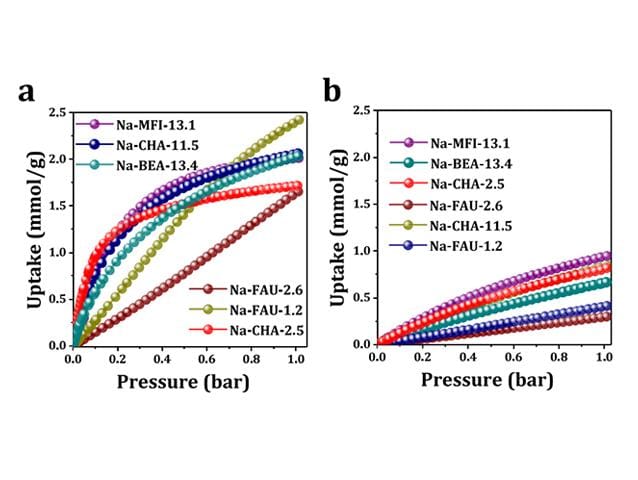

The versatile, high-performance instrument is designed for comprehensive gas adsorption testing. It supports the adsorption isotherm testing of corrosive gases like NH3 and SO2, as well as conventional gases such as N2, O2, CO, CO2, H2, CH4, and C2H6. The analyzer provides full functionality for analyzing specific surface area, mesopores, micropores, and ultra-micropores. With high throughput capabilities, it offers 3, 6, 9, or 12 analysis positions and features fully automated operation, including degassing and testing cycles. The analyzer automatically cycles through material adsorption performance evaluations, providing reliable, repeatable results.

- Isotherm;

- BET surface area;

- Pore volume and pore size analysis;

- N2/ Ar/ Kr adsorption analysis;

- Regular gas adsorption analysis (E.g. Nz, O₂, Ar, CO, CO₂)

- Combustible gas adsorption analysis (E.g. H₂, CH₄, C2H6)

- Corrosive gas adsorption analysis (E.g. SO2, NH4)

- 3/6/9/12 analysis ports;

- Pore size 0.35nm-500nm;

- Anti-corrosion design for pipeline, connection and seals;

- Full automatic In-situ activation& analysis;

- Vaccum System: 10^-2 Pa with mechanical pump, 10^-8 Pa with molecular pump.