Home / Product / BSD...

BSD-PHE AUTOMATIC HIGH PRESSURE ADSORPTION KINETICS ANALYZER

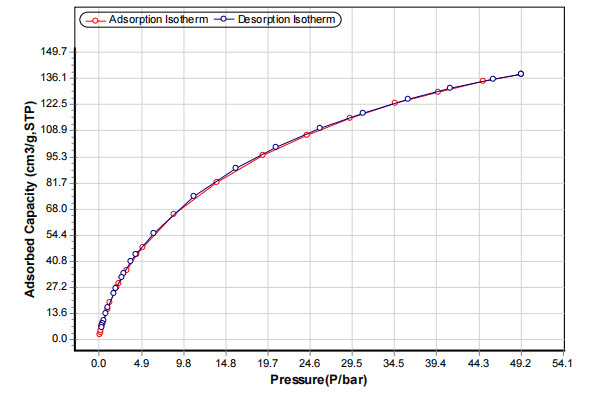

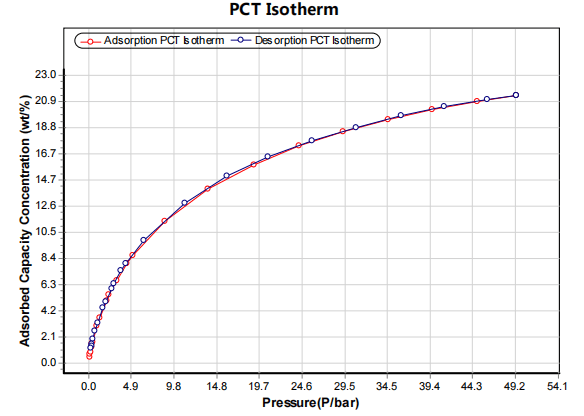

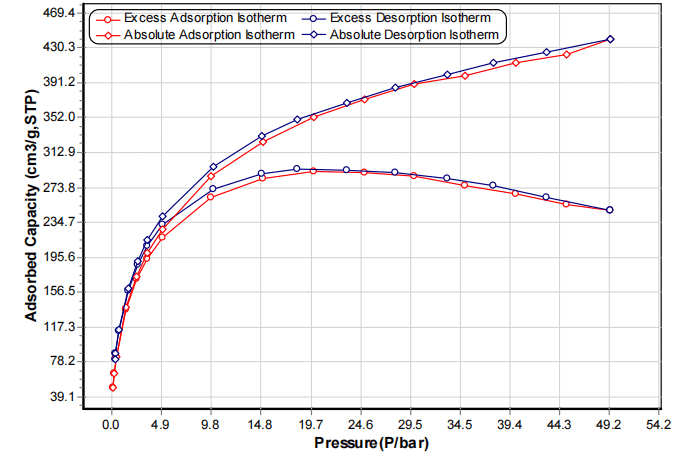

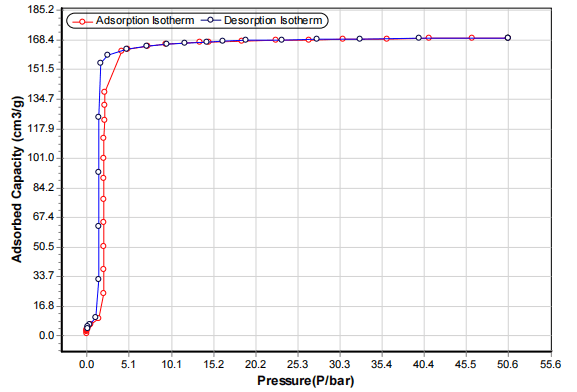

The BSD PHE High-Pressure Adsorption Kinetics Analyzer is a fully automated, high-efficiency instrument designed for precise gas adsorption analysis under high-pressure conditions. It offers advanced kinetics analysis at isobaric high pressure, making it an ideal and cost-effective alternative to traditional magnetic balance gravimetric analyzers.The system features an optional TPD (Temperature Programmed Desorption) module for programmed temperature desorption, as well as capabilities for hydrogen absorption and desorption kinetics testing. It also supports TPD desorption rate analysis, platform temperature control, and TPA (Temperature Programmed Absorption) hydrogen absorption rate testing, providing comprehensive insights into material behavior under varying temperature and pressure conditions.With its versatile testing options and high level of automation, the BSD PHE Analyzer delivers reliable, accurate results for a wide range of high-pressure adsorption and desorption applications.

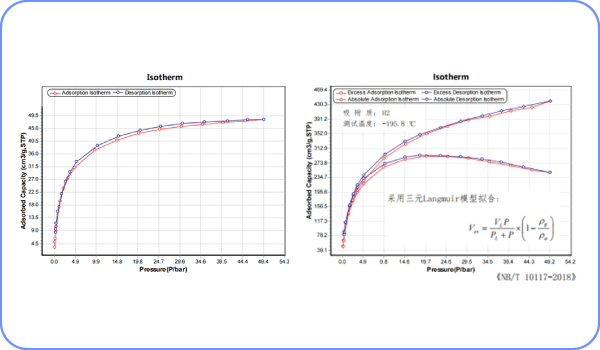

- High pressure adsorption analysis upto 20Mpa;

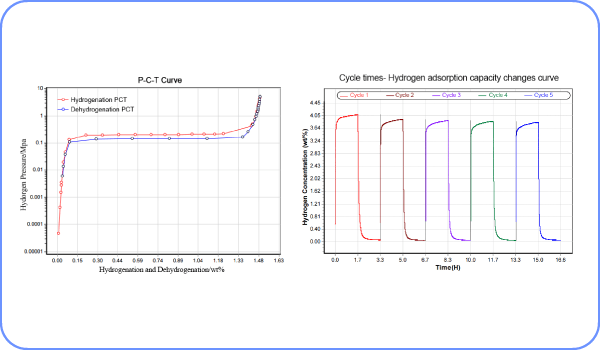

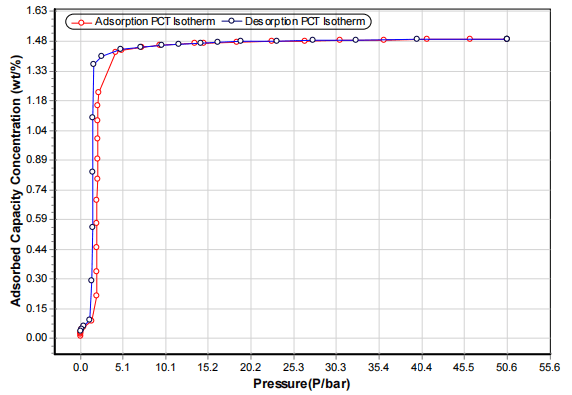

- Pressure composition isotherm PCT curve;

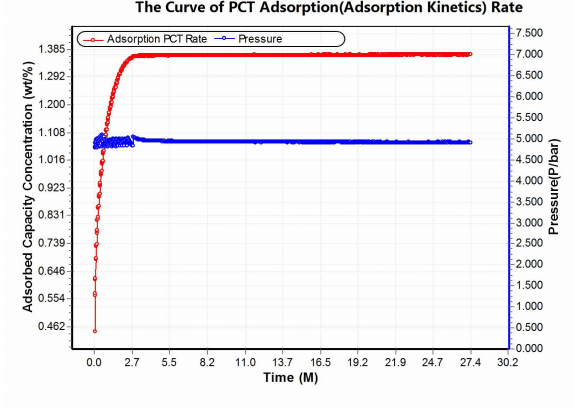

- Constant pressure adsorption kinetic analysis with volumetric method;

- TPD temperature programmed desorption;

- TPA temperature programmed adsorption;

- Simulating the constant pressure gas storage process;

- Research on shale gas and coalbed methane reserve assessment;

- Hydrogen storage PCT, hydrogen absorption and desorption cycle test;

- Research on the adsorption performance of porous materials;