| Model | BSD-VVS (Vacuum Static Method) | BSD-DVS (Dynamic Method) |

| BSD-VVS&DVS (full-function version, vacuum static + dynamic) |

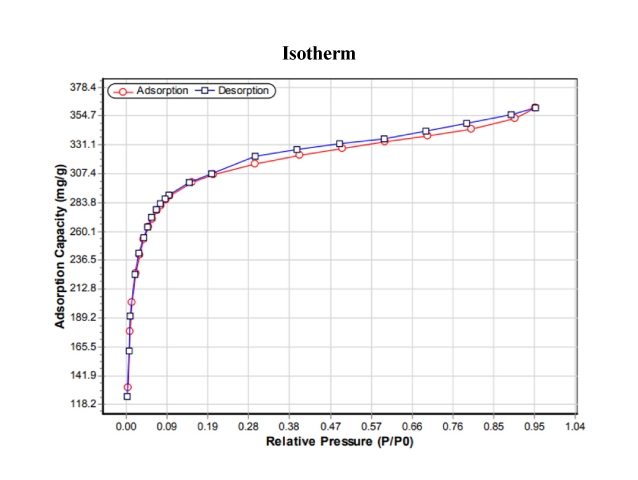

| Function | Adsorption-desorption Isotherms |

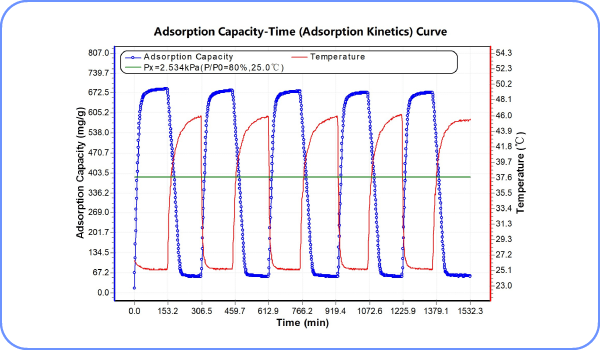

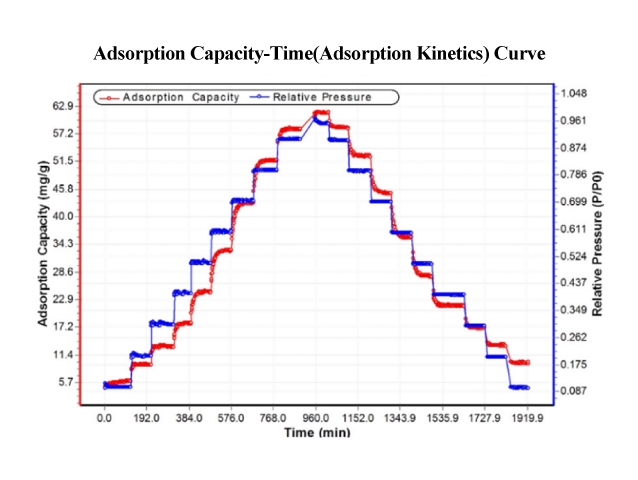

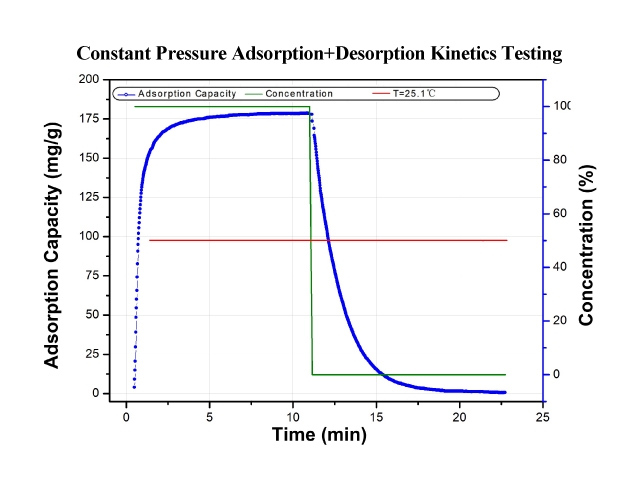

| Isobaric adsorption kinetics ( adsorption rate) Analysis |

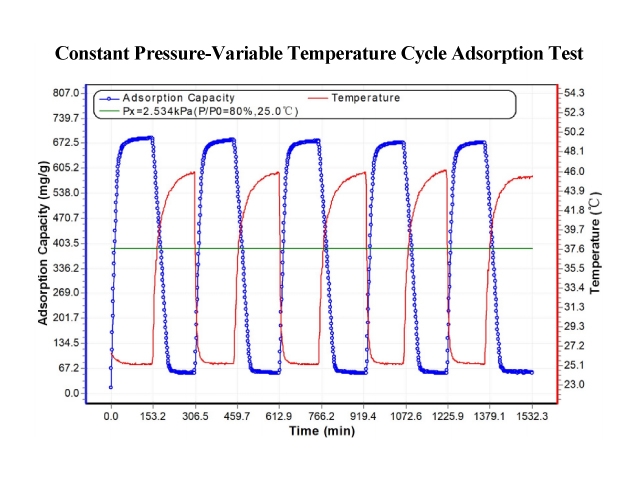

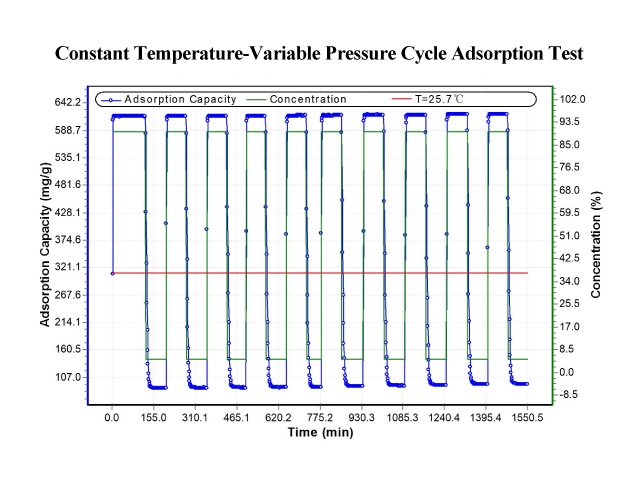

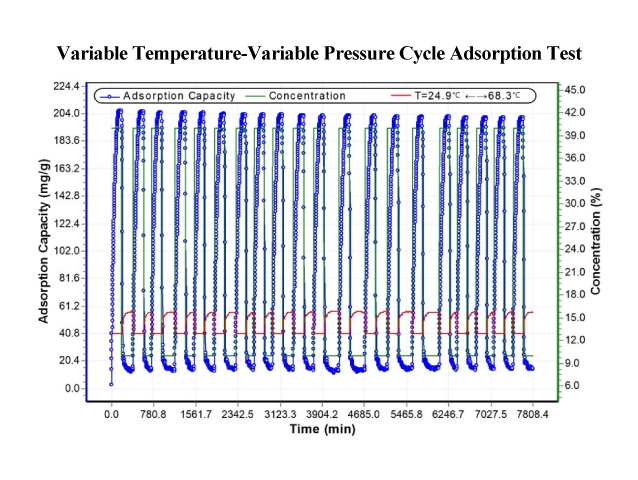

| Fully automatic adsorption cycle life evaluation |

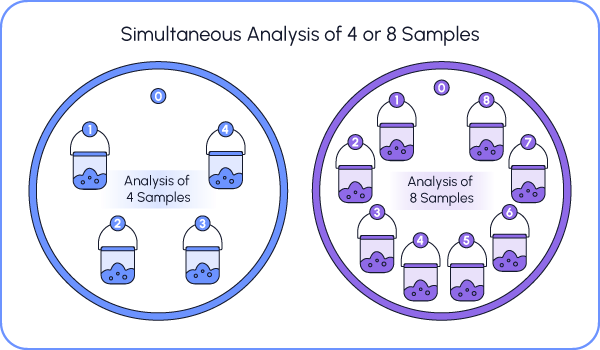

| Analysis Positions | 4 or 8 analysis positions; |

| Simultaneous analysis of multiple analysis positions in the same background environment |

| Microbalance Resolution/Range | Industrial microbalance, 1ug/5000mg, 1ug/10000mg (0.1ug/500mg optional); |

| Organic Vapor | yes | yes |

| Non-Corrosive Gas | yes | yes |

| Corrosive gas | no | yes |

| Auto-Switch Furnace and Waterbath (Optional) | Fully automatic switching between heating furnace and thermostatic water bath, Fast switch from activation to adsorption test |

| Auto Cyclic Test (Optional) | Automatic cyclic test of repeated adsorption and desorption to learn material durabilty and lifetime evaluation |

| Adsorption chamber temperature | Constant temperature bath, -5℃~120℃, accuracy ±0.1℃; |

| Thermostatic Pipeline | ~70℃ (optional 80℃), accuracy 0.1℃; |

| Steam generation | “Static Evaporation” Method | Bubbling method |

| Humidity | 0.1%~98% P/P00 | 0%~97.5% P/P0 |

| Reagent tube | 120ml(380ml optional) | 120ml Reagent condensation recovery |

| Sample Activation | Vacuum degassing, molecular pump high vacuum degassing function is recommended | Atmospheric pressure purge degassing |

| Room temperature ~ 300℃, accuracy ±0.1℃; | Room temperature ~ 250℃, accuracy ±0.1℃; |

| Programmed heating | 32-stage programmed heating to prevent pipeline contamination ; |

| Visual Process UI | Visual information of real-time sample weighting, accurately judge whether the sample is completely degassed; |

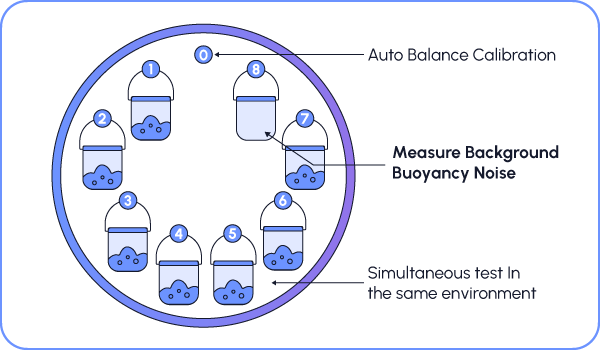

| Buoyancy correction | Mode 1: Buoyancy calculation mode (default); Mode 2: Blank buoyancy background subtraction mode; Mode 3: Background subtraction curve mode; |

| Blank position background Subtraction | Measure blank position to learn real influence of background buoyancy and for system subtraction calcuation; |

|

| Vapor removal | Vacuum mechanical pump + steam pump; Programmed steam removal; | Purging |

| Optional Molecular pump | molecular pump, vacuum degree> E-6torr; | / |

| Segmental pressure measurement | Dual pressure sensor segment test; Capacitive film pressure sensor | / |

| Pneumatic vacuum flapper valve | Pneumatic vacuum flapper valve with zero heat generation | / |