Home / Product / BSD...

BSD DVS Gravimetric Vapor Sorption Analyzer

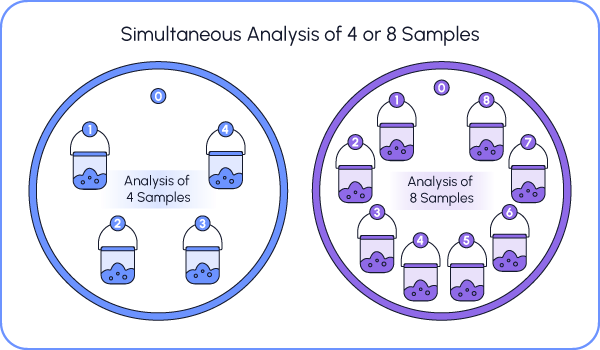

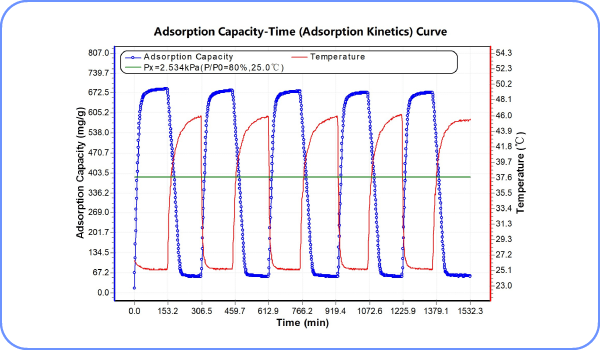

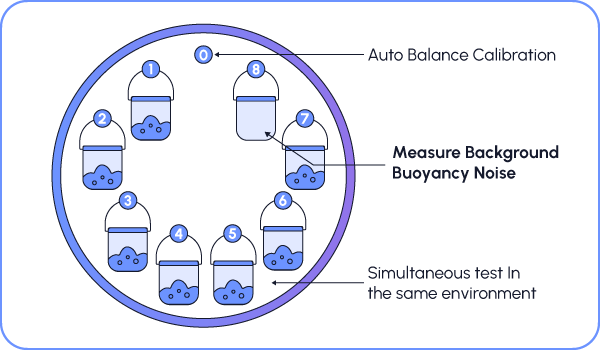

The Gravimetric Sorption Analyzer accurately measures the adsorption and desorption behavior of samples by directly weighing mass changes in real time before and after adsorption, under controlled relative partial pressures. Using a high-precision microbalance, it offers superior accuracy compared to volumetric methods, eliminating common sources of error such as temperature-induced zone distribution and non-ideal gas corrections.This analyzer overcomes the limitations of volumetric methods by enabling real-time, isobaric adsorption rate measurement and providing precise data on adsorption kinetics, which are essential for understanding material behavior.The BSD Dynamic Gravimetric Vapor Sorption Analyzer enhances this functionality with high throughput capabilities, allowing for the simultaneous analysis of up to 8 samples. Its fully automated cyclic testing feature significantly boosts laboratory efficiency, reducing the need for repetitive tasks and freeing researchers to focus on more complex analyses.