Home / Product / BSD...

BSD-VD12 Vacuum Degassing Station

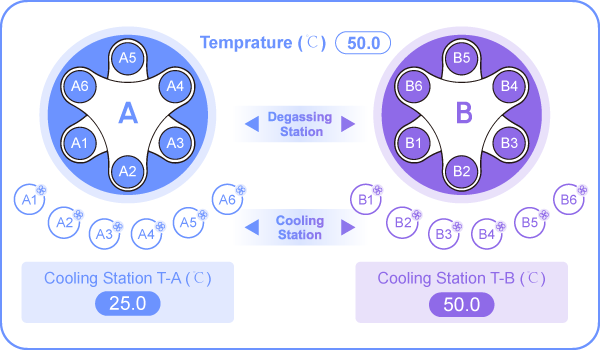

The VD 12 is a high-performance vacuum degassing system featuring two independent stations with 12 total positions for simultaneous degassing of different sample types. It offers precise temperature control, with a standard setting of 400°C and an accuracy of ±0.1°C, and a user-friendly 32-segment programmable touch-screen controller for easy operation. The system includes both **air-cooled and water-cooled positions** for optimal temperature regulation and utilizes **automatic pressure-controlled pumping** to ensure efficient high-vacuum degassing without sample loss. A built-in pressure sensor monitors degassing completion. An optional cold trap protects both sensitive samples (e.g., MOF, COF) and the vacuum system from contamination by organic reagents. The AD 12 is ideal for precise, simultaneous degassing of multiple samples.