01

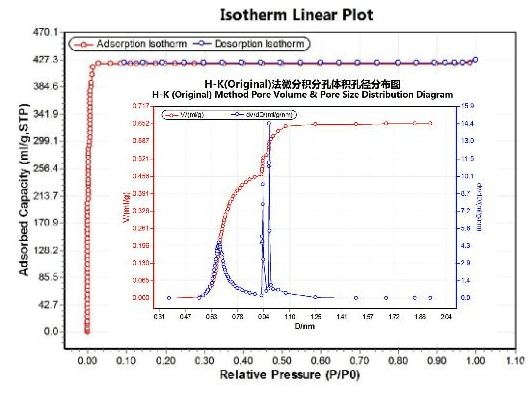

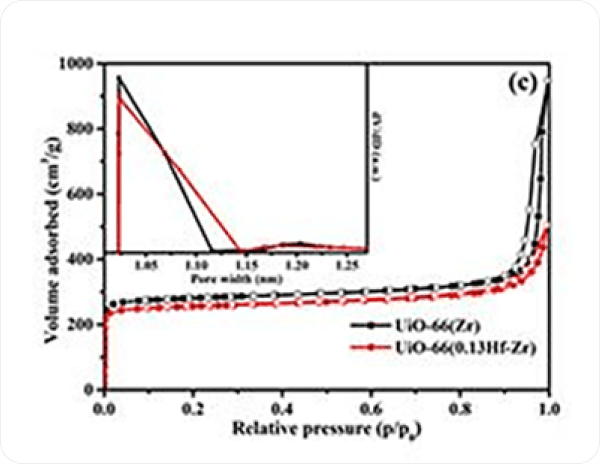

Basic Data

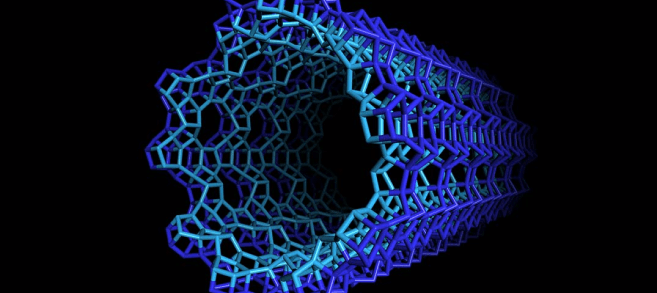

Gas adsorption analysis is a common method for the determination of BET surface area, pore size distribution and total pore volume. It can be used for pore characterization between approximately 0.35 and 500 nm.

02

Adsorption Capacity

Adsorption capacity is the amount of adsorbate that an adsorbent can take up per unit of mass or volume. BSD analyzers are designed to learn the adsorption amount with different kinds of gas, at different pressure or temperature.

03

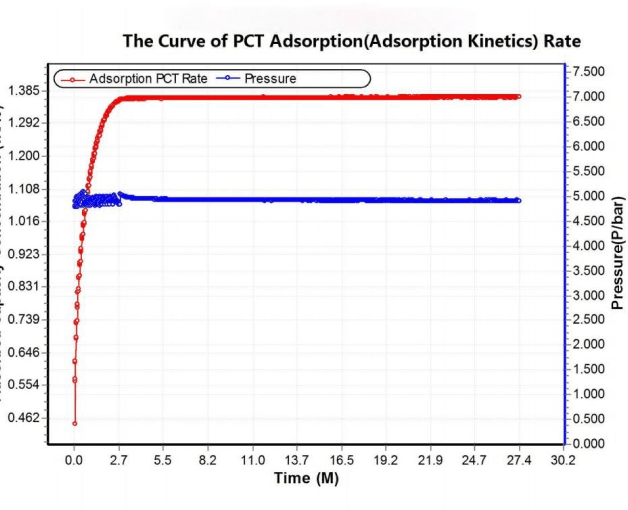

Adsorption Kinetic Assessment

Adsorption kinetics is the study of adsorption rate, the amount of adsorbent adsorbed as a function of time variation. Through the study of adsorption kinetics, the speed in the adsorption process can be obtained. It is beneficial to investigate the mechanism of the entire adsorption process and to assess the adsorbent quality.

04

Adsorbent Life Cycle Assessment | BSD Automatic Cyclic Adsorption

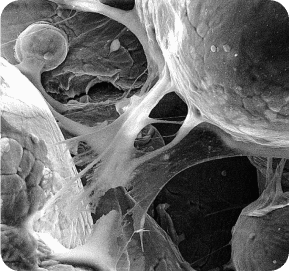

Life cycle assessment (LCA) is a tool that can be used to optimize experimental design, evaluate robustness, compare technologies and consider economic costs. To learn durability or robustness of adsorbent, Cyclic adsorption test (repeated multi-test) will be carried out. BSD analyzers are designed with automatic cyclic adsorption function, which saves researchers’ time and energy of repeated lab work.

05

Competitive Adsorption| Breakthrough analysis or membrane gas permeation

Competitive adsorption or selective adsorption are the key for gas purification or separation. Breakthrough analysis are lab level simulation of industry gas purification or separation application. The research has wide range of potential applications: CCUS carbon capture technology (capture of low concentration CO2 in the airCCUS carbon capture- recovery of high concentration CO2 in power plant exhaust gas ) Air purification- ( removal of air pollutantsAdsorption and separation of rare gases such as xenon and kryptonPreparation of hydrogen deuterium, 12C/13C, H2O/D2O and other isotope separation) Separation of isomers such as o-p-xylene, C4, C5, C6, Recovery of greenhouse gases such as Freon, Reforming hydrogen purification, Separation of CH4/N2/CO2 from coalbed methane, Electronic special gas adsorption purification, Adsorption separation of low carbon hydrocarbons, Nitrogen and oxygen separation/air separation, Alcohol and water separation, Removal of SO2 in flue gas.